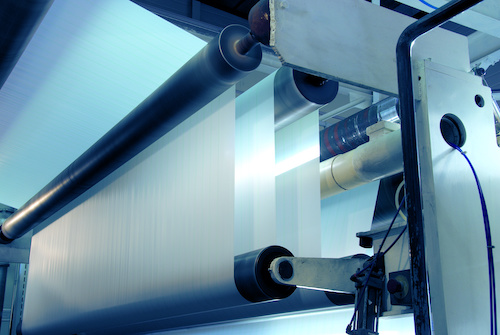

Web and print inspection

Foil, film, and web are the terms used to identify the layer that gets formed and rolled at very high speeds. Between forming and rolling, the best industry practice is to use machine vision to inspect 100% of the surface to detect and identify flaws. Only a few years ago, this sounded impossible or very expensive; today it is an affordable tool for manufacturers to increase product quality and solve or prevent problems in the production cycle promptly, preventing non-conforming products from reaching customers.

Specifically, prints and labels can be made on many materials, on coated or laminated products, and the result can be matte or glossy. Alkeria multiple cameras can be mounted in a multi-camera system to inspect any combination of prints and surface types.

Typical flaws are missed spots, scratches, smears, pinholes, and roll-marks, and depending on the surface texture, are detected in many ways: on uniform webs, like paper or metal, the software will look for areas that differ from this uniform background. If the surface is textured, the software will need to be more sophisticated in order to characterize defects.

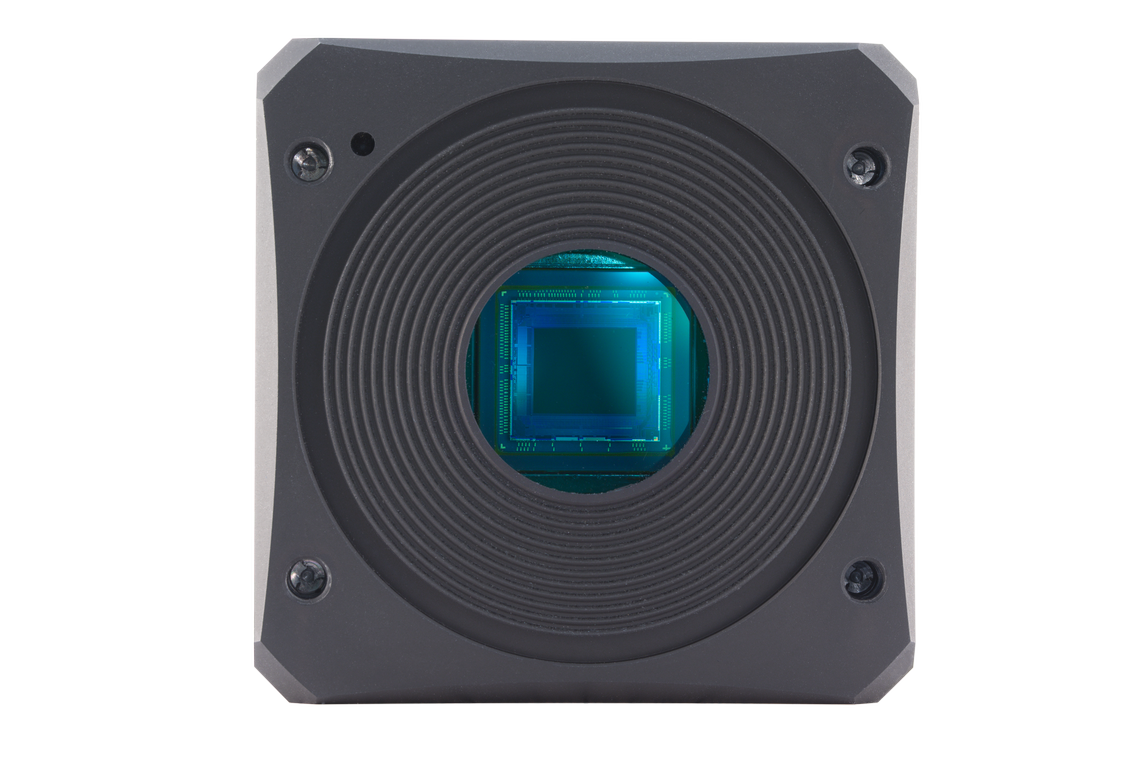

Web speed is a critical parameter in order to arrange the vision system, but you can find the right size for any process speed within Alkeria camera range. Besides, a USB3 connection makes it easier and less expensive to run the cables needed for transmission, compared to the ones required with a GigE interface.

Data can be elaborated in real-time, providing the timely feedback required to make the corrective actions needed, before the web becomes a finished product. These actions are numerous and may vary depending on the outcome of the vision reading. All information relevant to the flaw will be stored for further information.

When specific flaws take place, the operator’s notification and intervention may be requested; otherwise, an automated sequenced action can be executed, such as the elimination of a specific product or batch, or the intervention of a specific device aimed at removing the faulty material.

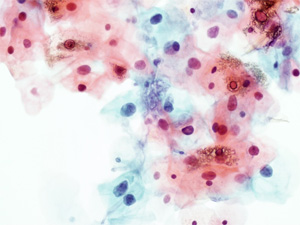

Medical imaging

Digital imaging has taken a primary role in medical diagnosing tools in the last decade, thanks to its consistency and high quality.

To get correct diagnoses and make better decision-making, hospitals, clinics, and doctors demand state-of-the-art image-capturing devices in a growing number of medical fields.

Given the consequences of such diagnosing and decision-making, critical components – such as cameras - need to match the highest rank of quality.

Some examples of medical imaging applications are:

- 2D and 3D confocal microscopy (for interferometric, brightfield, darkfield, fluorescence, etc.)

- 3D Dental

- Scanner ophthalmic instruments

- cell Sorting, counting, tracking

- vision blood testing systems

- surgical vision

- 3D imaging measurement systems

Alkeria is a leading supplier of high-quality ophthalmic imaging solutions, for retina inspection. However, the high-resolution/high-sensitivity cameras by Alkeria, offer the same high definition, a reliable resolution that is also required to detect the tiniest detail on the skin, or any other tissue and cell types.

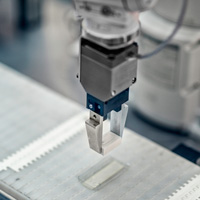

Pick-and-place applications

When it comes to automated components placed on an X, Y plan, high-performance vision systems become fundamental. After illuminating the product, a vision-guided system picks every tiny component, locates its destination, and places it correctly in a repeatable automated action.

“Pick-and-place” is a typical need of the semiconductor industry, where in controlled atmosphere environments, robotized systems inspect and assemble the semi-conductor wafers by “vacuum picking” the single components, while “looking” at the target destination via a high-performance, real-time vision system, at a very high-speed rate.

These systems are quite articulated and have a few criticalities, among which:- a state-of-the-art vision software

- an X, Y/rotating table

- a diffuse illumination system

- a high-performance camera to capture images continuously.

One of the most important aspects, as stated by expert system integrators is how the interaction between the machine vision system and the servo-motion control. Only flawless synchronization in the pick-and-place process guarantees perfect quality and avoids damage to the components.

One of Alkeria top capabilities is developing high-performing control systems coupling vision and movement, ensuring the best result for pick-and-place applications.

Pharma applications

Visual inspection

Nothing but the best quality standards are to be applied to pharmaceutical products: quality control becomes then a critical step in the production processes. In recent years, a large number of automated visual inspection and product handling systems have been installed; compared to manual inspection, automated visual control systems are way more accurate, effortless, and up to 5 times faster (with a speed of up to 10.000 pharmaceutical containers per hour).

Containers can thus be inspected to avoid the presence of particles in the product, contamination, cracks, or glass damage at the bottom, shoulder, and cap area. Inspection parameters (rotation speed, light intensity, etc.) can be preset and saved for each product type, to be loaded automatically for each different batch.

Alkeria high-performance line scan cameras can be a key success factor in these high-speed vision systems.

Track and Trace Solutions

A major concern in the pharmaceutical industry is protecting people from a significant counterfeiting phenomenon. Fake medicines are a real threat to human health, beyond reputational and economic damage for the same companies.

This is the reason why many countries – the European Union among them - have implemented laws to ensure full traceability from the manufacturer to the patient in order to avoid and ban the distribution of fakes.

This translates into an increasing need for integrating coding and code verification technology, with the so-called “track & trace” solutions.

Code reading technologies are at the heart of track and trace applications: they have to be able to check printed codes and make sure they are readable. For these systems, a combination of automation know-how, vision system integration, and mechanical handling engineering is critical to provide turn-key solutions.

Alkeria is a camera and motion control system designer that has the right expertise to work with a mechanical machinery company in order to integrate vision systems with the best results.

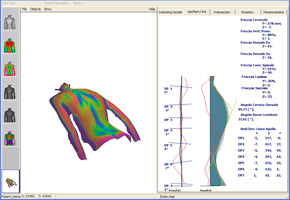

3D scan

Industrial-grade 3D scanners are used to provide accurate scans with high resolution, at high speeds. The purpose of the scanned images ranges from surface examination to metrology - measuring parts, tools and dies, castings, prototypes, etc. - in order to meet customers’ contractual/warranty requirements.

Previously, laser technology was used to measure distances in space between certain markups. Today’s laboratory devices can capture objects’ full surface geometry and primitives instead, with high precision and several benefits:

- 3D measures high accuracy

- better resolution of scanning parts

- fast data collection and real-time response/action

- complete dimensional analysis

- comprehensive reporting

- contactless measuring systems

- image capture of moving targets

Commonly these measures are used by development engineers to analyze such material properties (R- and N-values, FLC, Young's Modulus, etc.), component analysis (crash tests, vibration, durability simulation testing, etc...), and Finite Element Analysis. In order to support these features, interfacing with CAD systems is strongly required.

Alkeria’s state-of-the-art performance and integration capabilities guarantee successful and proficient results.

Anything special?

High-performance cameras can be applied for a wide range of applications, and beyond.

Outside the most common areas, several industries make significant use of industrial automation and machine vision for different purposes:

- automotive industry: inspection systems for metal sheets and small parts, component testing via 3D scanning, track and trace applications; robotics vision for testing and handling.

- food & beverage: fast-moving consumer goods such as baked product inspection, code scanning for random testing, microbial detection systems, 3D imaging for accurate volume measurements, printing inspection for packaging, fruit or grains counting, size sorting and ripeness inspection, container quality inspection, and more.

- defense, security & aerospace: track and trace of 1D or 2D code identifiers - alphanumerical or even braille - quality inspection of parts and more.

- electronics & solar: high-speed surface inspection of photovoltaic panels, pick-and-place vision systems for electronics assembly, accurate 3D inspection, and more.

- traffic, rail & transport: barcode scanning for pallets, airport controls, high-speed imaging for speed checks, high-speed road inspection, black box for ships or airplanes, trains, trucks, and cars, and more.

- sports, entertainment & broadcast: high-speed image acquisition for calculating track and trajectories of moving items –balls, people – high-speed imaging for slow motion analysis, use of infra-red imaging to reveal information that conventional cameras could not obtain.

What is your next application of machine vision going to be? Tell us about it, our specialty is supporting machine manufacturers and vision system experts with our know-how in high-performance cameras, servo-motion controls, and the latest software. Tell us your target, and we’ll find the way to get you there.